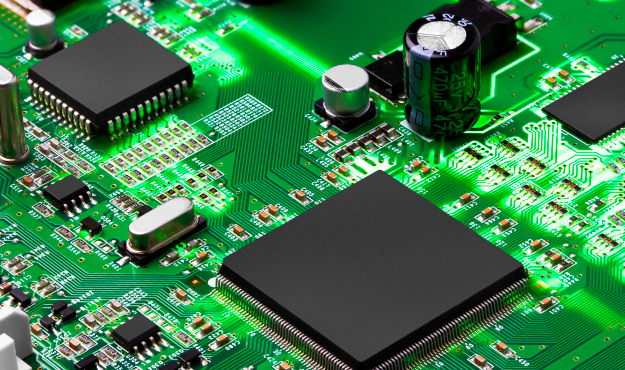

Individual forums skip thru several machines which region the electronic components of their right location inside the circuit. If floor mount generation goes for use to mount the additives, the forums first skip via an automated solder paster, which places a dab of solder paste at every element touch point. Very small components may be located by a “chip shooter” which swiftly locations, or shoots, the components onto the board. Larger additives may be automatically positioned. Some components may be too big or peculiar-sized for robotic placement and have to be manually placed and soldered later.

The components are then soldered to the circuits. With floor mount generation, the soldering is carried out via passing the boards via every other reflow method, which causes the solder paste to soften and make the connection.

Sixteen The flux residue from the solder is wiped clean with water or solvents relying on the kind of solder used.

Packaging

Unless the printed circuit forums are going to be used right now, they are in my opinion packaged in protecting plastic bags for storage or shipping.

Quality Control

Visual and electrical inspections are made all through the manufacturing system to hit upon flaws. Some of those flaws are generated by means of the automated machines. PCB For example, additives are occasionally misplaced at the board or shifted earlier than final soldering. Other flaws are because of the utility of too much solder paste, which can cause extra solder to float, or bridge, across adjoining printed circuit paths. Heating the solder too speedy within the very last reflow process can cause a “tombstone” effect wherein one give up of a component lifts up off the board and doesn’t make contact.

Completed forums are also tested for functional overall performance to make certain their output is inside the desired limits. Some boards are subjected to environmental checks to decide their overall performance below extremes of warmth, humidity, vibration, and impact.

Safety Considerations

The solder used to make electric connections on a PCB includes lead, that is taken into consideration a poisonous material. The fumes from the solder are taken into consideration a fitness hazard, and the soldering operations should be accomplished in a closed environment. The fumes must be given suitable extraction and cleansing before being discharged to the environment.

Many digital merchandise containing PCBs have become out of date inside 12-18 months. The capacity for these obsolete products getting into the wastestream and finishing up in landfills has many environmentalists concerned. Recycling efforts for electronic products consist of refurbishing older products and reselling them to customers that don’t want, or have get admission to to, more moderen, ultra-modern electronics. Other electronics are disassembled and the laptop parts are salvaged for resale and reuse in different merchandise.