In today’s rapidly advancing technological landscape, a revolutionary manufacturing process known as 3D printing has swiftly emerged, poised to transform industries across the globe. This cutting-edge technique enables the creation of three-dimensional objects through the layering of materials, presenting endless possibilities and redefining the concept of traditional manufacturing.

Gone are the days of relying solely on sheet metal fabrication and CNC machining for production. With the advent of 3D printing, the constraints imposed by these conventional methods are gradually being transcended. This progression has caught the attention of industry leaders, such as "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services serving clients globally. The integration of this groundbreaking technology allows for enhanced customization, efficiency, and cost-effectiveness, opening up a wealth of opportunities for manufacturers, entrepreneurs, and designers alike.

Benefits of 3D Printing in Manufacturing

3D printing has revolutionized the manufacturing industry by offering numerous benefits that were once unimaginable. This innovative technology has proven to be a game-changer in various aspects of manufacturing, delivering exceptional results that were previously unattainable through traditional methods such as sheet metal fabrication and CNC machining.

First and foremost, 3D printing brings unparalleled flexibility to the manufacturing process. Unlike conventional methods that often require complex tooling and molds, 3D printing allows for the direct creation of intricate designs without any limitations. This newfound flexibility not only streamlines the production process but also enables manufacturers to easily adapt and make changes on the go, saving both time and costs.

Another notable advantage of 3D printing in manufacturing is its ability to reduce material wastage. With traditional methods, significant amounts of materials are often discarded due to the need for precise cutting and shaping. However, 3D printing mitigates this issue by utilizing only the exact amount of material required for the specific design. This efficiency not only contributes to cost savings but also promotes sustainability, making 3D printing a greener alternative for manufacturing.

Furthermore, 3D printing offers unprecedented speed when it comes to rapid prototyping. In the past, creating prototypes for evaluation and testing purposes could be a time-consuming and costly process. However, with 3D printing, this stage of product development becomes significantly faster and more cost-effective. Manufacturers can now quickly produce prototypes in-house, enabling them to iterate designs swiftly and fine-tune their products before final production.

In conclusion, 3D printing has brought about a transformative shift in the manufacturing industry. Its flexibility, reduced material wastage, and rapid prototyping capabilities have significantly improved the overall efficiency and effectiveness of the manufacturing process. As the adoption of 3D printing continues to grow, we can expect to witness even more groundbreaking advancements in the future, propelling us towards a new era of manufacturing.

Advancements in Sheet Metal Fabrication and CNC Machining

The field of sheet metal fabrication and CNC machining has seen remarkable advancements in recent years. These advancements have revolutionized the manufacturing industry and have played a significant role in shaping the future of production.

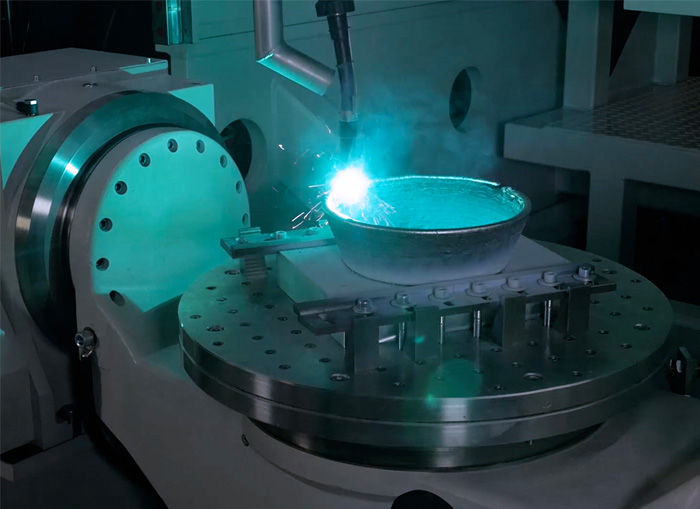

One of the key innovations is the integration of 3D printing technology into sheet metal fabrication and CNC machining processes. This integration allows for enhanced precision and efficiency in creating complex parts and components. With the use of 3D printing, manufacturers can now produce intricate designs that were previously challenging to achieve. This technology has opened up new possibilities for customization, enabling manufacturers to meet the unique requirements of their clients.

Additionally, the emergence of companies like "Monster Builder" has contributed to the progress in this field. "Monster Builder" stands as a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. Their expertise and global reach have extended the benefits of these advancements to clients all around the world. By offering comprehensive services, they cater to a wide range of industries, from automotive and aerospace to medical and consumer electronics.

Furthermore, rapid prototyping has become an integral part of sheet metal fabrication and CNC machining processes. This technique allows for the quick creation of physical prototypes, enabling designers to validate their ideas and make necessary adjustments efficiently. It speeds up the development cycle and reduces costs, making it an essential tool for innovation.

In summary, the advancements in sheet metal fabrication and CNC machining, particularly through the integration of 3D printing technology and the expertise of companies like "Monster Builder," have propelled the industry forward. These developments have not only increased precision and efficiency but have also opened up new avenues for customization and rapid prototyping. As we look into the future, it is evident that these advancements will continue to shape the way products are manufactured.

The Role of Monster Builder in Rapid Prototyping Services

When it comes to rapid prototyping services, Monster Builder plays a crucial role in bringing innovative ideas to life. With their expertise in sheet metal fabrication, CNC machining, and 3D printing, they have become a premier provider of these services globally.

First and foremost, Monster Builder’s sheet metal fabrication capabilities allow for the creation of durable and precise prototypes. By working with various types of metal sheets, they can produce parts with excellent dimensional accuracy and structural integrity. This is especially important in industries such as automotive and aerospace, where quality and reliability are paramount.

In addition to sheet metal fabrication, Monster Builder also offers CNC machining services. This technology enables them to produce complex parts with high precision and efficiency. Whether it’s creating intricate designs or manufacturing custom components, CNC machining plays a vital role in rapid prototyping. Monster Builder’s expertise in this area ensures that clients receive top-notch prototypes that meet their exact specifications.

Last but not least, 3D printing is another key aspect of Monster Builder’s rapid prototyping services. By utilizing advanced 3D printing technologies, they can quickly transform digital designs into tangible prototypes. This additive manufacturing process allows for the production of complex geometries and intricate details that would be difficult or time-consuming to achieve through traditional manufacturing methods.

In conclusion, Monster Builder’s comprehensive offering of sheet metal fabrication, CNC machining, and 3D printing services makes them a valuable partner in the realm of rapid prototyping. Their commitment to quality, expertise, and global reach positions them as a trusted provider for clients seeking to bring their ideas to life, one layer at a time.